Many big names in the automotive industry are suspending production in the world’s most populous country due to restrictions on the movement of people and materials.

A Tale of Two Automotives

The two big names suspending production in China are Toyota and Tesla.

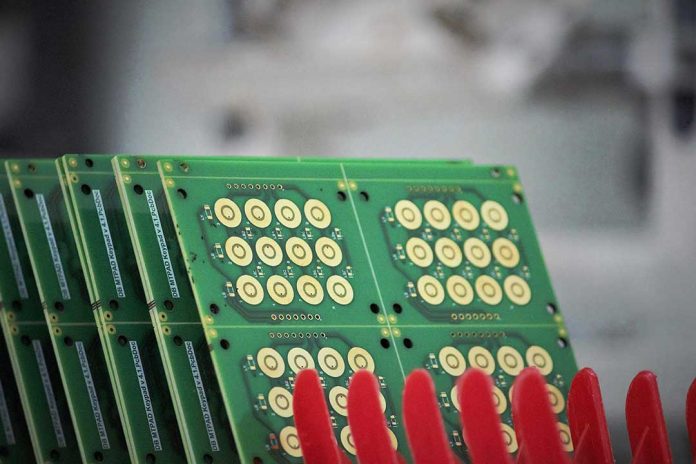

On May 10, 2022, Toyota announced that it had revised its May Production Plan due to a shortage of semiconductors and the strict lockdown. The lockdown in Shanghai has affected the production in other parts of the world, too; the company has said that it would suspend operations of 14 lines at eight plants in Japan between May 16 and May 21.

According to the global production plan, the worldwide production for May was supposed to be 7,50,000 units, but now due to the lockdown in Shanghai, it is projected to be 7,00,00 units.

Another company that is facing major consequences of the lockdown is Tesla. According to the China Passenger Car Association (CPCA), the company’s sales went down by 98% in April compared to the earlier month. After reopening the factory on April 19, the automaker sold 1,512 vehicles out of 10,757 units produced. In March, the sales were 65,814 units.

On May 10, Tuesday, the company produced only 200 units, which is a big gap compared to the 1,200 units it had produced after reopening the factory that closed due to lockdown. The prime reason behind the dropped production is the difficulty in obtaining supplies.

Looking for New Routes to Drive the Sales

To ramp up the production and sales, Toyota and Tesla need to search for other markets that can supply them with the parts needed. After China, the US and Europe are the biggest automotive parts suppliers that can play a major role here. In terms of the market, India, Germany, Japan, Brazil, and France are big names that help the firms get back up on their feet.