CNC Machines: From The Simple To The Most Complex

Are you curious about the detailed engineering of jet wings? Do smooth automobile bodies or workplace chairs with an ergonomic layout also captivate you? These wonders seem disparate; however, there is a common foundation: Computer Numerical control (CNC) machining.

Mastering Computer Numerical Control

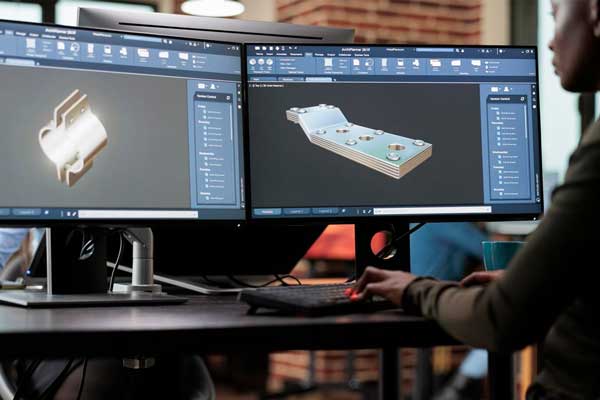

CNC machining, Computer Numerical Control Machining, stands as one of the most powerful automation applications. This industrial procedure, directed via computer systems, converts CAD (Computer Aided Design) files into finely honed gadgets with an unmatched degree of precision. Picture a professional sculptor utilizing technology to etch metal with accuracy and pace.

The Craft of Taking Away: How CNC Machining Works

CNC machining differs from 3-D printing, which matches the layer with the aid of the layer. Starting with a stable block known as a blank or workpiece, G-code—a specialized language—controls diverse reducing tools’ moves in this manner. These equipment are like properly crafted chisels that slowly carve the material into its last form.

Precision is one of the wonderful functions of CNC machines. It has lengthy blanketed accuracy and tolerance as metric standards measuring all the way down to the micrometer level. CNC machines are the top of precision manufacturing, perfect for packages that require high accuracy, together with plane elements, clinical gadgets, and extraordinarily complicated watch components

Human abilities in the digital age

CNC machining technology ensures greater accuracy through greater digitization of the entire design, planning, execution, and control process

When it comes to CNC machines, it is clear that they are highly automated; however, they are still on the human side. Experienced engineers use computer-aided design (CAD) modeling to create their designs. Technologists, also called device professionals, bridge the gap between theory and practice, making them important actors. CNC machines work best on mathematical controls, with operators understanding tool selection, material properties, and cutting order.

A Multiplicity of Uses: A Brief Overview of CNC Machining

We’re absolutely blown away by the potential of CNC machines—increasing availability! It recognizes metals in their traditional and current forms, such as aluminum and copper, and composite materials, such as thermoplastics. This allows everything from mobile devices without composite parts to an equally important innovation, adjustable seats based on employee anatomy data.

The future of CNC machines: An image of the developing landscape

CNC machining techniques have also been updated due to technological advances. In the long term, more modern processes will be developed to achieve more accurate results, cut machining time, and process a wider variety of products. This ensures that CNC machining has been a priority in modern production for many years.

Conclusion: A Precision Match Made in Heaven

CNC machining epitomizes the convergence of advanced generation and human creativity. Its ability to transform digital designs into bodily gadgets with excessive precision is unequaled, making it quintessential across numerous industries. In our upcoming articles, we will discuss specific styles of CNC machines, expound on vital considerations while designing for CNC machining, and discover destiny potentialities in this dynamic discipline to be tackled.

Also Read:

- How to Find a Manufacturer to Transform Ideas into Products

- How to Turn Ideas into Successful Startup Firms

- The How and Why of Creating New Product Ideas

- Patent: Definition, Economic Benefits, Patent Law & Global Insights

- The Franchise Business Model Explained: To Expand Globally

- Indian plastic manufacturers have a wide-open ground to grow: Here’s how